Web Chair

What we did

3D Printed PLA Chair

Showcase

Private Collection

Description

A Tribute to Timeless Design

What started as a lighthearted idea among friends—”What if we 3D printed a Herman Miller bent plywood chair?”—quickly turned into a serious design challenge. We’ve always admired the iconic silhouette of the original and wanted to understand it more deeply by reverse engineering the design.

However, as we began the process of 3D printing the prototype, we faced several obstacles. Traditional plywood chair designs rely on methods like heat pressing and the use of molds, which make it easy to shape strong, durable forms that can last for generations. 3D printing, on the other hand, comes with its own set of limitations: it’s time-consuming, expensive in terms of material, and often less durable.

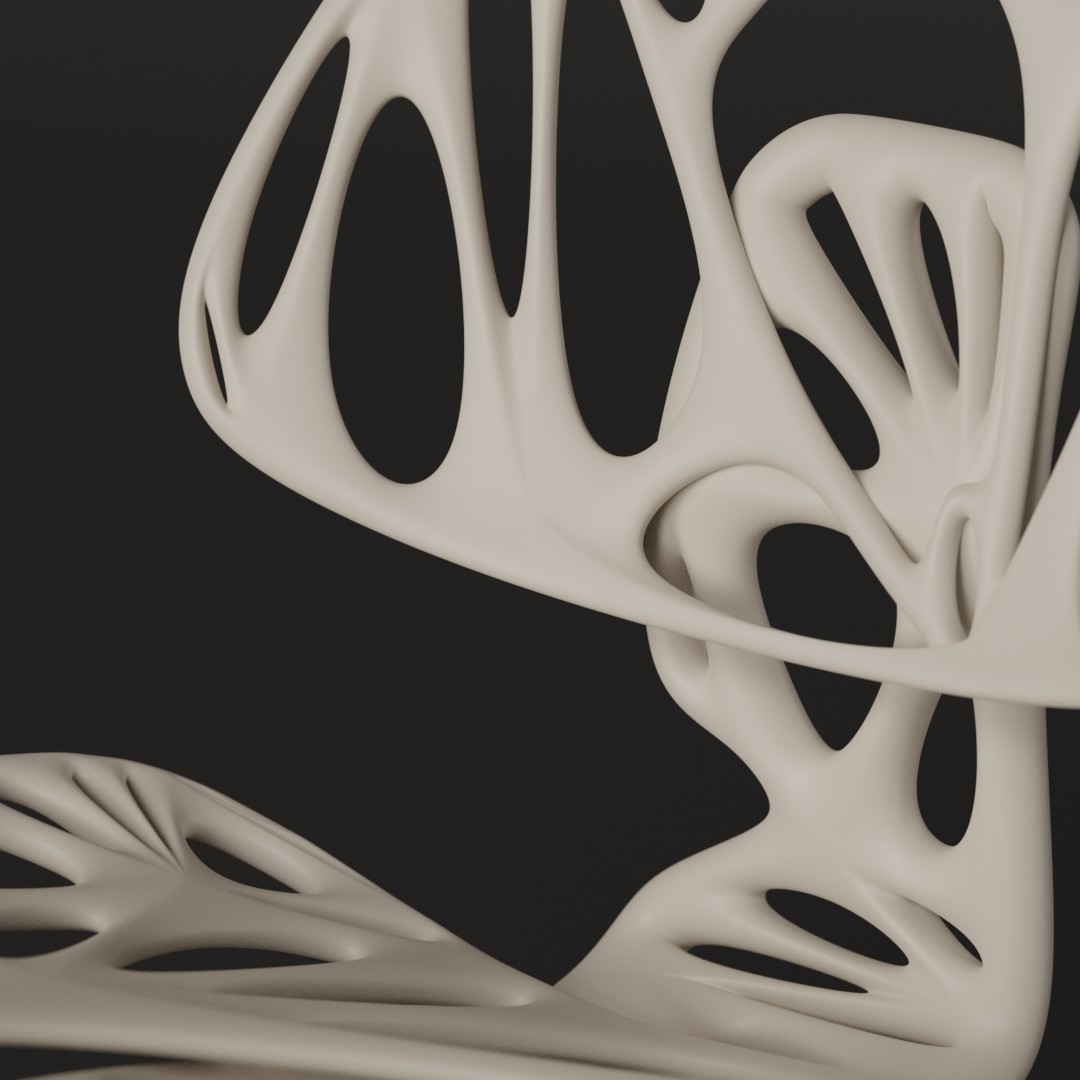

Recognizing these constraints from the outset, we sought creative solutions to cut down on time and material use while maintaining structural integrity. This led us to incorporate material optimization through cutouts, a technique known as topology optimization in engineering. By strategically removing material from low-stress areas, we were able to preserve the essential silhouette while reinforcing the areas that bear the most load, resulting in a piece that is both lightweight and strong.

The final result is not only a tribute to one of our favorite designs but also a sculptural, experimental piece that pushed our understanding of form, function, and material. It’s a love letter to timeless design, reinterpreted through the lens of modern technology.